Hauling Britannia’s 10-foot inflatable RIB dinghy eight feet up from the water on the davits required two people, and it was also interminably slow with the dinghy sometimes swaying wildly on the tackles.

Hauling Britannia’s 10-foot inflatable RIB dinghy eight feet up from the water on the davits required two people, and it was also interminably slow with the dinghy sometimes swaying wildly on the tackles.

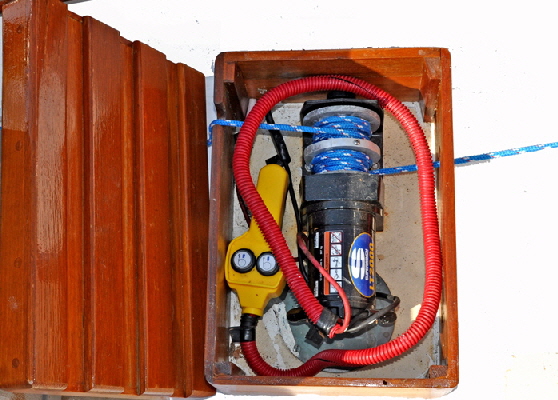

I had watched people at boat ramps, hauling their boats on trailers using an electric drum winch on the back of their vehicles. I found one of these at Northern Tool Inc., (Superwinch LT2000 Model Model 1220210). It is a 12-volt drum winch with a wired remote up and down button.

This winch now effortlessly hauls my 120 Lb dinghy, and a 55 lbs outboard to the head of the davits in 38 seconds. The ‘down’ button lowers it slightly quicker, and both can be operated by a child.

I don't hoist them together when making passage, I clamp the outboard to its bracket on the stern rail. But I often lift them both attached at night at anchor, mainly to prevent theft. This is a great improvement on using twin tackles.